Beyond Trucking: Optimising Supply Chain Management

Trucking plays a crucial role in supply chain logistics, serving as the primary mode of transportation for moving goods over long distances. Its efficiency in delivering products from the manufacturers directly to consumers is unparalleled.

However, while trucking is vital, it is just one part of the supply chain. In today’s interconnected and globalized world, businesses need to look beyond trucking to optimize their operations.

Leveraging Technology and Predictive Analytics

The use of predictive analytics in logistics allow users to make proactive decisions by analysing data from different points in the supply chain. These data help businesses spot potential problems before they arise and take preventative measures to mitigate risks

It also optimises algorithms, improving resource allocation and supply chain efficiency. Additionally, automating routine tasks with predictive analytics enables workers to focus on higher-level strategic planning and innovation.

By incorporating digital solutions into their operations, businesses can streamline their supply chains, reduce operational costs, and boost customer satisfaction by ensuring timely, reliable deliveries.

Adapting to Market Changes

In a fast-changing global environment, supply chains must be agile and resilient to handle disruptions, such as pandemics (e.g. COVID-19), geopolitical tensions, and natural disasters.

Supply chain agility and resilience is achieved through strategies like diversifying suppliers, investing in risk management, and having contingency plans. By building these into their supply chain, businesses can not only survive disruptions but also gain a competitive edge.

During the COVID-19 pandemic, many companies diversified their supplier base across different regions. This approach reduced their reliance on a single supplier or region, ensuring supply chain continuity despite lockdowns. For example, manufacturers were able to maintain essential material flow to meet customer demands through alternative supply chains, which safeguarded their operations.

KPMG Singapore highlighted the importance of having contingency plans for suppliers and logistics routes to stand against such disruptions. The Economic Development Board (EDB) of Singapore also emphasised how businesses were forced to rethink their supplier strategies to ensure continuous operations during the pandemic, showing the value of diversification in creating more agile and resilient supply chains.

Collaboration Across the Supply Chain

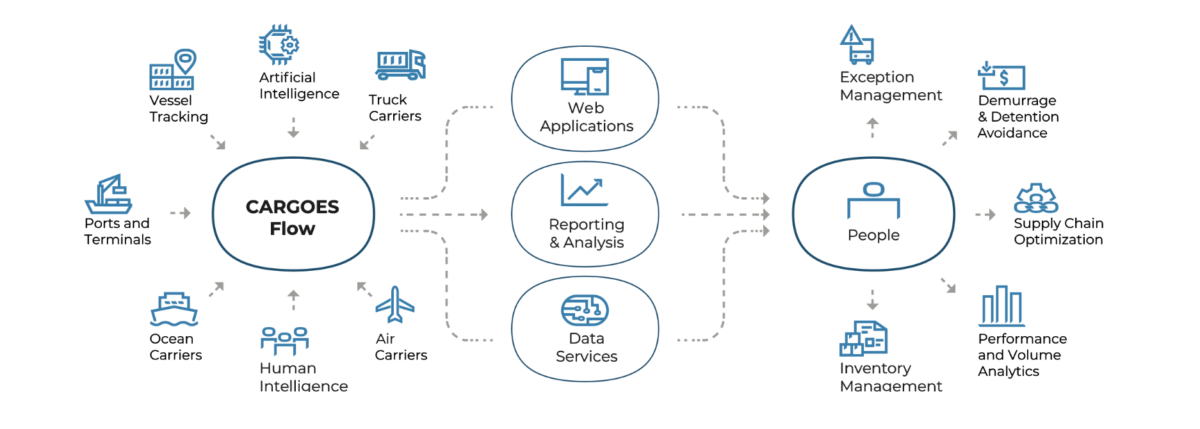

Collaboration is key to efficient supply chain management, especially when intermodal transport and multiple touchpoints are involved. Tracking shipments from start to finish requires coordination between trucking companies, rail and port operators, and customs officials.

Effective collaboration ensures seamless operations, better scheduling, and shorter lead times. Predictive analytics-driven platforms encourage data sharing, enhancing visibility across the supply chain and reducing disruptions. This integration leads to cost savings and improved efficiency, making it easier for businesses to meet customer expectations.

Image from DP World.

The Future of Supply Chain Management

Looking ahead, supply chain management will be shaped by a combination of advanced technologies, sustainability initiatives, and innovative strategies. Predictive analytics, automation, and smart systems will continue to revolutionize the industry by improving decision-making, minimizing human error, and streamlining operations.

As these trends emerge, it’s essential for businesses to reassess their supply chain strategies and look beyond traditional methods. By embracing digitalisation, multimodal transport, leveraging predictive analytics, and prioritizing sustainability, companies can build more efficient, resilient supply chains that are future-ready.

Now is the time to take proactive steps to optimize your supply chain, ensuring your business stays competitive and adaptable in an ever-evolving global market. Interested to find out how to better optimise your supply chain management?

Contact us to find out more!

References:

- https://throughput.world/blog/predictive-analytics-in-supply-chain/

- https://kpmg.com/sg/en/home/insights/2020/04/covid-19-and-global-supply-chains.html

- https://www.ibm.com/topics/supply-chain-analytics

- https://lot.dhl.com/supply-chain-diversification-success-strategic-partnerships/

- https://www3.weforum.org/docs/WEF_Navigating_Global_Value_Chains_Disruptions_2021.pdf