A Sustainable Shift: Transitioning from Air to Sea Freight in Pharma Logistics

What is Cold Chain Logistics

In cold chain logistics, temperature-sensitive goods are transported and stored in a controlled environment to maintain quality, efficacy, and safety.

It involves refrigerated transport, specialized packaging, and real-time monitoring to ensure that items like vaccines, biologic, and fresh produce remain viable from the point of origin to their destination.

Strict regulatory compliance is essential to prevent spoilage, contamination, and health risks, adhering to standards set by agencies like the FDA and WHO. These regulations mandate proper handling, storage, and transportation to maintain the safety and efficacy of products like pharmaceuticals and food.

How is Pharmaceuticals Cold Chain carried out?

Cold chain logistics for pharmaceuticals requires a balance between temperature needs, transportation modes, and packaging types to ensure that pharmaceuticals are safely and efficiently delivered.

- Varying Temperatures

Flexibility in temperature control is key to maintaining pharmaceutical efficacy, from frozen to room temperature, depending on the item’s stability.

- Air or Sea Freight Options

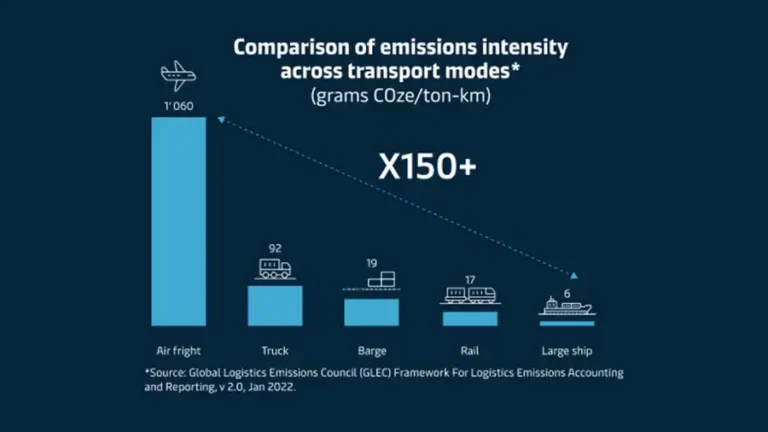

Sea freight offers a more eco-friendly and cost-effective option for pharmaceuticals. However, air freight is faster and better suited to time-sensitive products with short shelf lives.

- Active vs. Passive Packaging

Active packaging, like refrigerated containers, ensures long-term temperature stability but is costly and heavy. Passive packaging is lighter and cheaper but only offers temporary protection, making it less reliable for long trips or in extreme conditions.

Why is there a shift?

The worldwide healthcare logistics market is set to go from the $130bn in 2023 to around $152bn in 2026. The growing pharmaceutical market, especially for biologics and vaccines, has increased demand for these services.

At the same time, sustainability concerns and decarbonisation goals are pushing companies to adopt greener options. While the rising air freight costs are driving companies to source for more efficient and affordable cold chain solutions. Organisations are starting to seek alternatives to traditional air transport, which has been the dominant mode for pharma freight.

Concerns for Pharmaceutical

While advancements in e-commerce have improved logistics capabilities, enabling supply chains to better deliver personalised goods, the pharmaceutical sector faces unique challenges that require specialised infrastructure.

In contrast to consumer retail, which often relies on bulk shipments and can tolerate some variability in delivery times, pharmaceutical logistics require meticulous planning and precise execution.

Pharmaceuticals must be transported under strict temperature controls and handled with care to maintain their efficacy, whereas consumer goods are generally more robust and less time-sensitive.

This difference necessitates specialised infrastructure, such as refrigerated containers and real-time temperature monitoring, to ensure the products reach their destination in optimal condition.

How can Haulio help?

Our smart digital container trucking platform and solutions empower a strong regional alliance of 800 trucking and haulage companies and a growing digital fleet of 10,000 first-mile vehicles, to transact 2.3 million TEUs of cargo annually to serve the everyday needs of businesses and communities.

By trucking with Haulio, pharmaceutical companies can be assured of up-to-date visibility and enhanced predictability of the trucking process. Additionally, optimising processes through our smart platform can also help track carbon emissions and ensure timely delivery of temperature-sensitive goods.

Looking for cold chain container haulage? Reach out to us!

References:

- https://www.maersk.com/news/articles/2024/03/21/transforming-pharma-logistics

- https://www.freightos.com/freight-resources/air-freight-vs-ocean-freight-making-the-decision/

- https://www.dpworld.com/insights/expert-opinions/the-future-of-the-medical-supply-chain

- https://www.dhl.com/discover/en-nz/logistics-advice/logistics-insights/cold-chain-pharmaceutical-logistics

- https://theloadstar.com/ocean-carriers-are-hungry-for-a-slice-of-the-growing-pharma-shipment-pie/

- https://globallogisticsnews.com/ocean-carriers-eye-pharma-growth-market/

- https://www.supplychainbrain.com/articles/34798-five-critical-challenges-facing-pharma-supply-chains