Everything you need to know about Container Doors

In the shipping industry, the most common object used would be the shipping containers, but did you know there are about 3 main types of container doors you can use for your containers? Furthermore, what are the different things that are commonly found on the back of container doors? Everything you need to know about them will be found here.

Common Types of Container Doors

Type 1 Doors

This type of door is usually meant for storage with frequent use.

Description: Flat steel panels, lightweight, single locking bar

Advantages: Light weight makes them easier to use than shipping container doors

Recommended for: Storage containers for frequent use

Type 2 Doors

The second type of doors are much more commonly seen. They are more secure due to the inclusion of more locks, and are usually seen on shipping containers.

Description: Thick corrugated steel, rubber seals, two locking bars

Advantages: Watertight and very secure

Recommended for: Heavy duty storage, especially construction sites

Type 3 Doors

The third type of door is a mixture of the first and second type. The door is more secure than type 1, but lighter than type 2. This type of door is more advantageous for frequent access but requires the content to be secure.

Description: Flat steel panels, lightweight, double locking arms

Advantages: Combines the best features of Type 1 and 2 doors

Recommended for: Storage of items easily damaged by moisture – ie paperwork, fabrics, furniture

What are the signs printed on the back of container doors?

Shipping container doors often times have things printed on them. Some are quite easy to understand such as the company logo and the weights. But what about the rest of the signs?

These signs represent:

- A) Container Number

- B) Check Digit

- C) Container Owner or Shipping Line

- D) ISO Code

- E) Max Gross

- F) Tare Weight

- G) Net Weight

- H) Cubic Metre

- I) Classification Society Label

- J) Certifications

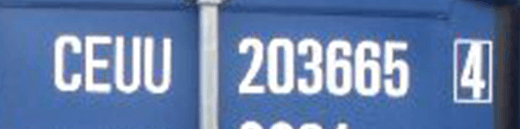

A. Container Number

Located at the top right hand corner, this is the unique container number used to identify each container. It comprises of 4 alphabets and 7 numbers.

The container number identification system has been created by the International Standards Organisation under their code IS06346:1995(E).

As per this code, the container identification system consists of:

- Owner code – 3 letters (in above example CEU) The owner code is also unique to the company.

- Equipment category – 1 letter (in above example, U denoting a freight container Other categories being J for detachable container related equipment (such as Genset) and Z for trailers and chassis)

- Serial number – 6 numbers (numbers ONLY)

- Check Digit – 1 number (numbers ONLY)

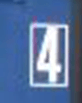

B. Check Digit

The Check Digit is the last number in the Container Number sequence. It is very important as it can be used to identify the validity of the container number. Did you know, you can go to BIC’s Check Digit Calculator and when you type in the first 4 letters and first 6 numbers, they will generate and show you the last digit. Pretty cool right?

C. Container Owner or Shipping Line

This is the logo or name of the company that owns or operates the container. This could be a shipping line, such as Hapag Lloyd, or a container leasing company such as Belle.

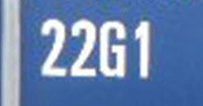

D. ISO Code

As per the International Standards Organisation under their code IS06346:1995(E), each container is given a unique ISO Code in order to avoid any misunderstandings when identifying the type of container it is. For example a standard 20′ container is called Dry Van (DV), General Purpose (GP), Standard (SD), Normal, Dry Container (DC) etc in different countries.

As these names are all different in different countries, these names might not be recognised in some countries. Therefore as a standard, the ISO code of 22G1 (in this example) is used to denote that the container is a 20′ container, 8’6″ high with a tare weight of 2,250 KG

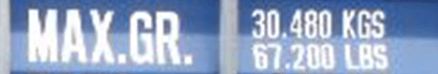

E. Max Gross Weight

In this example – 30,480 KGs is the maximum weight that the container can carry including its own tare weight of 2,250 KGs.

F. Tare Weight

This is the weight of the container when it is empty and it is given by the manufacturer upon the end of the manufacturing and labeling process. This is important to consider because it tallies into the overall weight that is being carried onto a ship and it might cause problems if not tallied together.

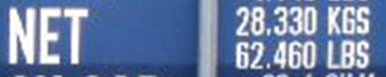

G. Net Weight

The total weight that this container, excluding the weight of the empty container. This is inserted so that clients know how much weight they can assign to the containers.

The Net Weight is also sometimes referred to as the payload that the container can take.

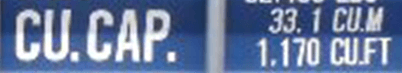

H. Cubic Capacity

This is the maximum volume in cubic capacity that can be packed into the container. Misdeclaration of volume in the Bill of Lading might lead to an extra charge especially if the cargo is sold in terms of volume.

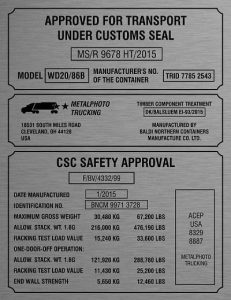

I. Classification Society Label

Every container has to be checked by a classification society to ensure that it’s strength, hardiness, cargo and seaworthiness and this label is used to identify the classification society that checked this container for verification purposes.

J. Certifications

Every container should have a valid safety approval plate called the Container Safety Convention(CSC) plate in order for it to be used in international trade. This is in accordance to the International Convention on Safe Containers of 1972.

The role of the CSC plate is to confirm that the container has been checked and validated to be in working condition for transport.

This plate has all the details of the Owners, maximum gross weight, other technical data, and Approved Continuous Examination Programme(ACEP) that certifies that the container has had an examination within the last 30 months.

Caution Stickers

Some containers also have stickers to indicate whether it is High Cube or a standard container. This is important because a High Cube container is heavier than a standard container, coming in at 8775lbs compared to the standard container’s 8000lbs. This, when factored into hundreds of containers, will lead to a huge weight increment that, if unaccounted for, can jeopardize the shipments.

Others

Some containers transporting chemicals or other items will have indicative signs on the back of container doors so that the handlers know how to handle them.

Questions?

We’re happy to help! Fill in the form below and we’ll get back to you shortly.