Everything You Need to Know about Reefer Trucking

About Refrigerated Containers (Reefers)

Refrigerated containers are often also referred to as reefers, and are one of the main types of shipping containers used in transporting goods.

Reefer containers are used for the shipment of temperature sensitive, perishable cargo such as meats, fruits and vegetables. This container type relies on external power to keep the internal temperature regulated. A genset, or generator set, is a unit that is usually attached to a reefer to cool the container. Reefers generally come in 20ft and 40ft, and are commonly made from a weathering steel known as ‘cor-ten’ steel.

How Reefers Work

It is important to note that reefers are intended not to cool the product, but to maintain the temperature of the product. The process of refrigeration is thus not the addition of cold air, but the removal of heat from the air inside the trailer.

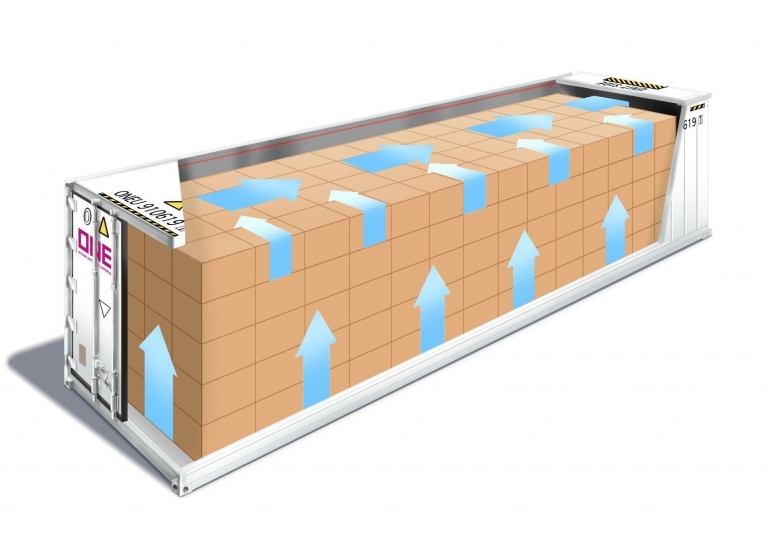

Reefer containers are bottom air delivery units designed to distribute chilled air from the floor, via a T-shaped decking.

The three main components of the refrigeration unit are the:

- Evaporator coil

- Compressor (which powers the evaporator coil)

- Small diesel engine (which powers the compressor)

Variations in air pressure create air flow. As air from inside the reefer passes over the evaporator coil, it removes heat and redistributes the now colder air back throughout the reefer.

There are two different ways to run the refrigeration unit — cycle or continuous. Running the refrigeration unit in cycles reduces diesel consumption, but also creates more temperature variance.

Many products require continuous cooling. Ripening produce, for instance, generates heat, and requires a steady stream of cool air to maintain a consistent temperature.

Some frozen loads are less temperature sensitive and can withstand slight temperature variances — in these scenarios, cycling may be okay.

Understanding the commodity specifications is thus crucial for truckers as they are responsible for the product from the moment it is loaded onto their trailer until it is unloaded.

Importing Reefers

When the reefers arrive at the port, they will be unloaded from the vessel and plugged in at the yard to ensure that the internal temperatures are maintained.

When your driver has collected the container and is transporting it to the destination, the reefer will be unplugged from the electricity source. Not to worry though! In Singapore, the maximum travel duration is 1.5 hour. As the reefers are designed to be heavily insulated to preserve the cold temperatures, the internal temperature of the cargo will not change drastically.

However, once your reefer has reached its destination, your driver needs to ensure that the reefer is plugged in and that the genset is running during unstuffing.

Reefer Port Charges

When importing reefer containers, you should also take note of the various tariffs imposed at the port.

Below are the additional port charges relevant for reefers in Singapore:

- Supply of electricity, including connecting and disconnecting the reefer at the port’s storage yard:

- 20ft: S$2.20 per hour or part thereof

- >20ft: S$3.30 per hour or part thereof

- Connecting/Disconnecting services on board a vessel:

- S$15

- Pre-trip inspection to ensure that the genset of reefers are working:

- 20ft: S$80

- >20ft: S$90

Do also take note of the free storage period (FSP) and the port storage charges if the reefers are stored beyond the FSP. Reefers have a free storage period of 72 hours in Singapore.

Exporting Reefers

For export, empty reefers can be collected from depots/yards to be transported to your warehouse for stuffing.

Depending on your cargo requirements, you will need to inform the depot whether you need to pre-cool or pre-set your reefer:

- Pre-cool: Your reefer will be pre-cooled to your desired temperature prior to collection.

- Pre-set: Your reefer will be pre-set to your desired temperature but the genset will not be turned on. However, it will automatically cool to the set temperature once it is plugged in at the destination for stuffing.

However, do note that it is generally not necessary to pre-cool your reefer. Especially in a tropical climate like Singapore’s, a large quantity of water droplets may form on the interior surface when the doors of a pre-cooled container are open in a warm ambient environment. Furthermore, the condensates may drip from the roof of the container and cause stains or weaken the structure of the cargo. Although these condensates will subsequently be removed through the evaporator coils of the genset, ice may be formed when the condensate passes through the evaporator coils, causing it to go into a short defrost mode. The more heat and humidity the refrigeration unit must remove, the lesser the cooling capacity available for the main objective of cooling the cargo itself.

It is thus recommended for products to be pre-cooled to the required carriage temperature before being packed into the container, unless the container is loaded in an airlocked cold tunnel in cold storage.

Stuffing Your Reefer

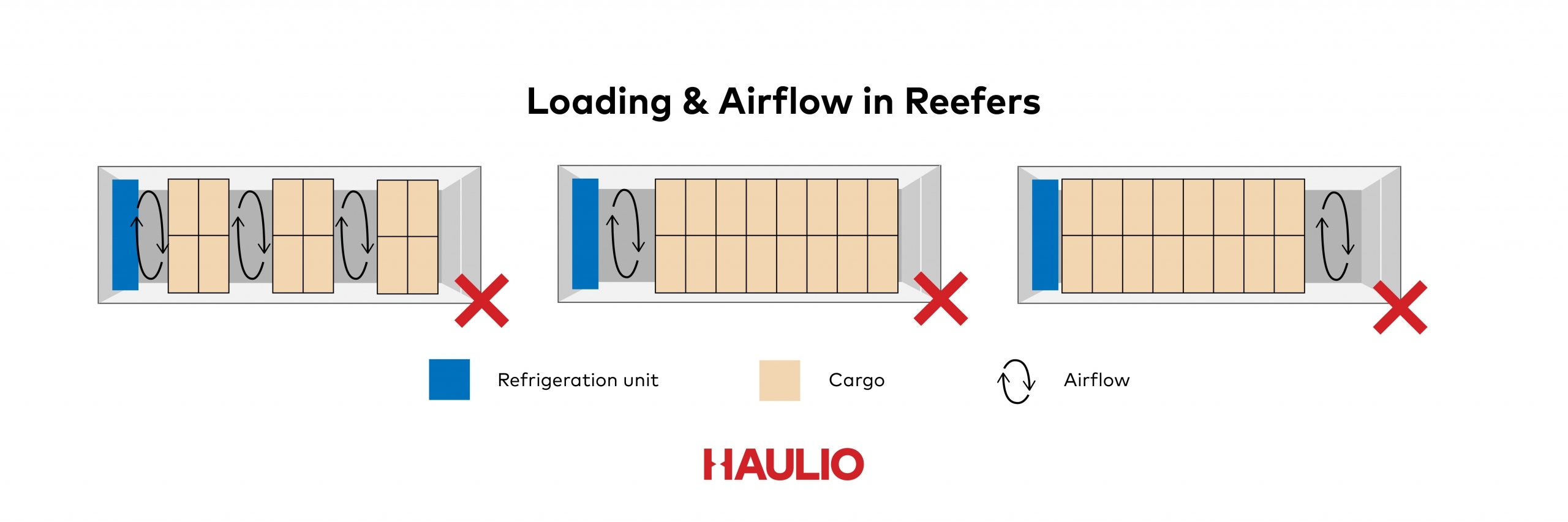

The stuffing and placement of cargo will directly affect the flow of air within the reefer. It is thus essential for you to stuff your cargo correctly.

In the case of chilled cargo, the cargo should be placed throughout the floor with spaces in between, to force the cool air to flow through both the cartons as well as the product, throughout the entire load.

In the case of frozen cargo, if the cargo is pre-cooled to the correct carrying temperature, it is only necessary for air to circulate around the periphery of the load. A block stow (i.e., one that has no deliberate spacing between any of the packages or pallets) is all that is required. However, it is necessary to ensure that air can circulate under, over and to each side and end of the stow.

Some general tips on stuffing a reefer:

- Cargo should not be stuffed beyond the end of the T-floor.

- Cargo should not be stuffed above the red load line.

- Cargo must be stable on the floor and tightly wedged so it doesn’t shift during passage.

- Unit must always be set at the proper carrying temperature and this set temperature will vary according to the cargo being loaded.

- Dehumidification controls must be checked.

- Products should always be pre-cooled to the required carriage temperature before being packed into the container, unless the container is loaded in an airlocked cold tunnel in the cold storage.

- Ventilation setting is of utmost importance and must be set at the correct level.

- Make sure there are no restrictions for airflow and any gaps through the pallets or doors need to be sealed for proper air circulation.

Things to Note When Stuffing Your Reefer

1. Air Circulation

As air will follow the path of least resistance, there should not be any restrictions for airflow and any gaps between the pallets and the doors must be closed using cardboard or even wood. This will then force the air to circulate correctly and reduce the potential for heat sinks (warm air continuously circulating) near the doors.

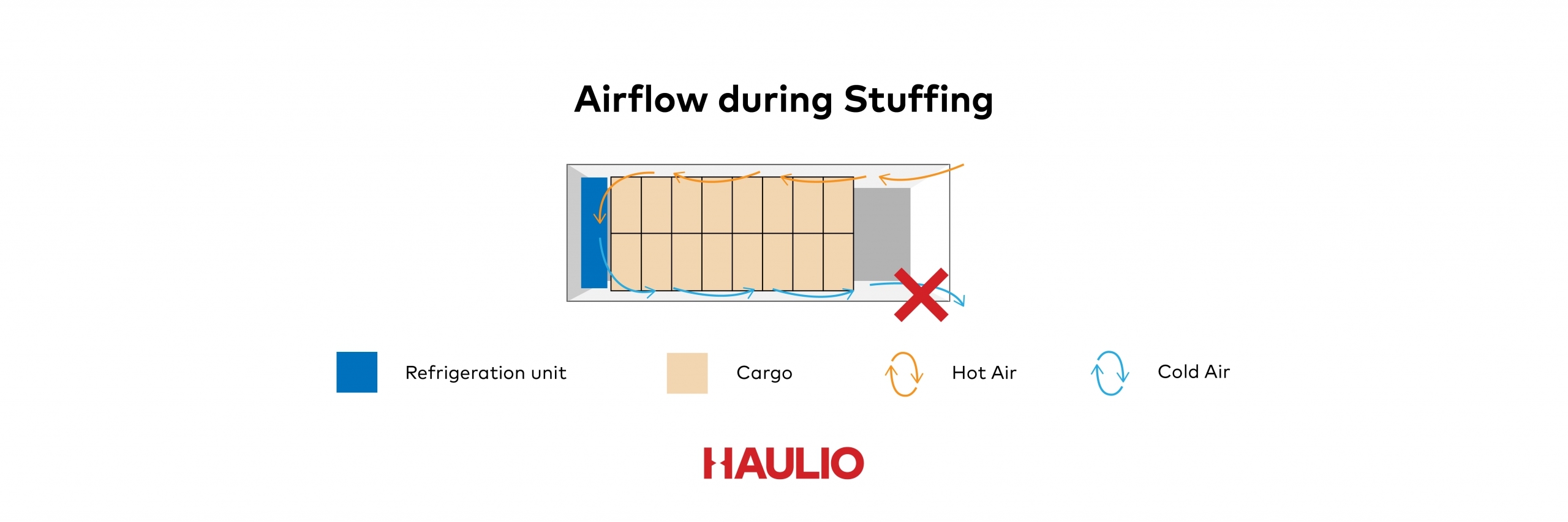

2. During stuffing, the refrigeration unit should not be turned on.

When the ambient temperature is warmer than the cargo, operating the reefer with the rear doors open will not cool down the cargo. Rather, the introduction of hot ambient air will heat up the cargo.

When hot humid air enters the reefer, moisture condenses on the cold cooling coil and turns to ice. Cooled air escapes through the rear door, and the cycle continues. Once stuffing is complete and the doors are closed, the reefer could run for hours with a partially iced-up cooling coil. This would reduce its cooling effect and put the cargo in danger until the unit completes a defrost cycle.

Checking Your Reefer - Pre-Trip Inspection (PTI)

As reefers are usually used to transport fresh groceries or temperature-sensitive cargo, it is essential to ensure the cleanliness of the reefer prior to its usage.

The Pre-Trip Inspection (PTI) is an extensive inspection done on empty reefer containers to ensure that the reefer machinery is running properly at the correct settings and that the container is clean and in sound condition. The PTI is usually conducted at depots, prior to the collection of the container by the customer for stuffing.

Here is a general checklist to inspecting your reefers:

Note: The guidelines below should not replace or override PTI procedures recommended by the manufacturer of the reefer container or the procedures set up by the shipping company.

- Check fasteners, bolts and suspensions, hatches and doors on the machine. Replace or repair if necessary.

- Check water cooler receiver couplings are not seized/jammed and are not damaged or missing. Replace or lubricate where required.

- Ensure compressor mounting brackets are intact and all bolts are properly tightened.

- Clean condenser coil where required and check for excessive corrosion, leakage and structural damage.

- Check wiring terminals/connections in control box/external wirings, including the RCD connections.

- Ensure wiring to all the contactors is secure and wired correctly. Check for burned connectors and replace if required.

- Carry out insulation check on components including electric heaters using megger test (min 3 meg Ω).

- Ensure the control box door can be secured correctly and seal is in good order. Check RCD antenna.

- Check that the drain hose from the evaporator section is not clogged or damaged.

- Check moisture indicator. Check filter drier for deterioration. Replace when deemed necessary.

- Check power cable is at least 18m long with maximum 2 splices. Ensure proper splicing.

- Check for cable damages and internal wiring/connectors of plug. Replace as deemed necessary.

- Check pipes, connectors and components for leakages and cleanliness.

- Remove all debris from the cable tray.

- Check working condition of fresh air exchange damper. Close air ventilation damper (excluding AV+).

- Ensure the reefer box has been inspected including cleanliness of the box, condition and position of the kick plate. The container should be cleaned of all debris and previous cargo.

- Check reefer unit back panel is properly secured.

- Ensure doors are securely closed.

Reefer Booking Checklist

Booking a reefer? Use the checklist below to see what you check the information needed for you to book one:

Note: The guidelines below should not replace or override procedures set up by the shipping company.

- Specify origin and destination

- Provide a detailed description of the product being shipped e.g. commodity name, quantity, weight, cubic measurement, and type of packaging (e.g. boxes, drums, pallets).

- Specify preferred equipment size e.g. 20ft or 40ft HC.

- Highlight preferred temperature settings in °F or °C.

- Specify fresh-air exchange requirements in CFM or CMH.

- Indicate modified or controlled atmosphere requirement:

- Gas composition (O2 and CO2 in %)

- Type of scrubber, if required

- Indicate shipment availability date at origin and required delivery date at destination.

- Specify special handling requirements (e.g. genset, dehumidification percentage level and cold treatment).

- Provide any documentation requirement, including legal requirements.

- Inform booking office if container pre-cooling is required.

Keen to Find Out More?

Get in touch via the form below and we’ll get back to you shortly!